Customized development ・ QMS

Category:

Detail

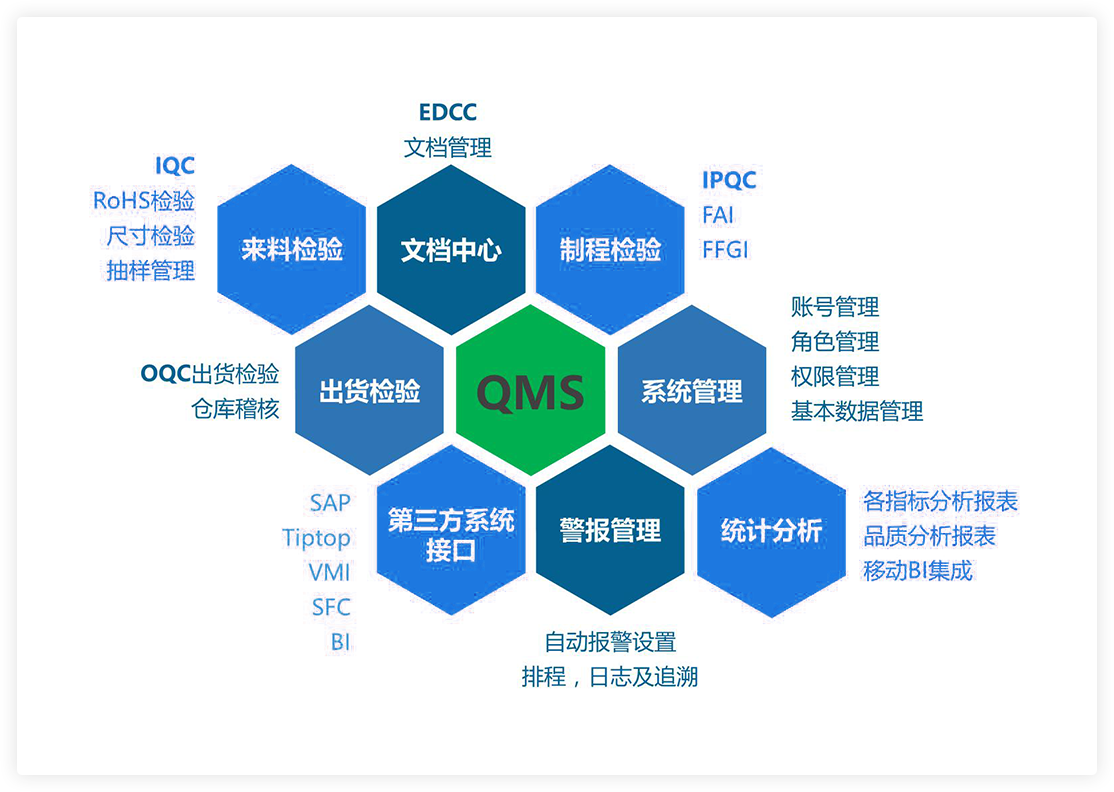

The QMS quality management system is a new generation of QMS products developed independently on the. NET platform, which combines the implementation experience and accumulation of MES projects in the manufacturing industry, and achieves configurability and service-oriented architecture. We can provide customers with comprehensive manufacturing workshop information solutions such as dispatch order management, process control, process management, quality management, maintenance management, traceability management, data collection, statistical analysis, etc.

Characteristics of QMS system

1. Real time monitoring of work order status. The starting quantity, completion quantity, backlog status, and quality inspection results of work-in-process products are clear at a glance;

2. A powerful data collection engine and integrated data collection channels (RFID, barcode equipment, PLC, CNC equipment integration, etc.) cover the entire factory manufacturing site, ensuring real-time, accurate, and comprehensive collection of massive on-site data;

3. Multiple query criteria such as time, product number, and order number can be used to query and analyze output;

4. Real time query of daily and monthly production progress reports to intuitively understand changes in product production through trend charts, better helping enterprises better arrange future production;

5. Various quality analysis reports: statistical reports on pass rate, defect rate, scrap rate, etc. Intuitively reflecting the current causes of quality defects and the number of defects caused, providing an accurate basis for enterprises to improve product quality and reduce losses caused by defects;

6. Comprehensive and complete product traceability function, collecting various status information such as processing information, quality information, material information, personnel information, equipment information, etc. during the plan execution process, forming a complete product traceability chain. The system automatically establishes a detailed product traceability file for "people, machines, materials, methods, environment, and testing".

Effect of QMS implementation

1. Transparency of manufacturing execution process: Through the QMS system, detailed production process data such as process output, work order transfer status, inspection, and product defects are collected in real-time, and a summary analysis report tool is provided to provide effective basis for production management decisions of different management levels in enterprises.

2. Shorten product manufacturing cycle: saves a lot of manual work processes and shortens the manufacturing cycle of the product. At the same time, real-time information collection and feedback eliminate various production process delays caused by information asymmetry, enabling production management personnel to grasp first-hand production information in real-time outside the production workshop, respond quickly to unexpected situations, and integrate output with planning more closely.

3. Improving product quality: By monitoring the entire production process of the product, providing relevant basic data and analysis tools to quality inspectors, we can assist enterprises in daily quality analysis and periodic continuous quality improvement. Real time monitoring and early warning of the legality of the process, product rate, and fluctuation of defect distribution have been carried out, providing effective prevention for problems on the production line.

4. Reduce production costs: By monitoring and warning the production site in real-time, prevent problems from occurring, and reduce the number of product repairs and rework. And based on various statistical analysis electronic reports, it saves time, manpower, and material resources, realizes paperless production in the factory, and subsequently reduces the use of manpower and other production resources.

QMS application

From 2016 to present: Implementation and operation and maintenance of multiple QMS projects at Chongqing Changan Automobile Co., Ltd., Changan Ford Automobile Co., Ltd., and Chongqing Changan Kuayue Vehicle Co., Ltd.

Consultation hotline:+86-13908307100, 13752990427

Office phone:+86 023 63948774, 63115900, 63115950

Fax:+86-023-67881453

Website: www.jnabs.com

Email: yiekj@yiekj.com

Address: 25th floor, Qibo Building, No. 99 Jinyu Avenue, North New District, Chongqing.

Previous

Next

Previous

Next

OTHER PRODUCTS

I WANT TO CONSULT