MES Production Management Solution

Overview of the plan

The MES production information management system is designed for the workshop execution layer of manufacturing enterprises. Based on the demand for production process information control and integration of upstream and downstream information, it operates with standardized production management processes to create a solid, reliable, comprehensive, and feasible manufacturing collaborative management platform for enterprises.

Core technology and innovation of the plan

1. Planning and scheduling, the manufacturing department plans and schedules the production order of the workshop based on the production situation on site every day, and supports business personnel to make adjustments at any time according to the actual situation.

2. The system automatically binds the tag number with the work order based on the production scheduling situation, and generates the vehicle VIN code according to the national algorithm. The tag number can be reused.

3. Integrate with on-site LED screens in the workshop to release production status and various information.

4. Build a data query and analysis system to facilitate remote monitoring of workshop production by leadership and management departments.

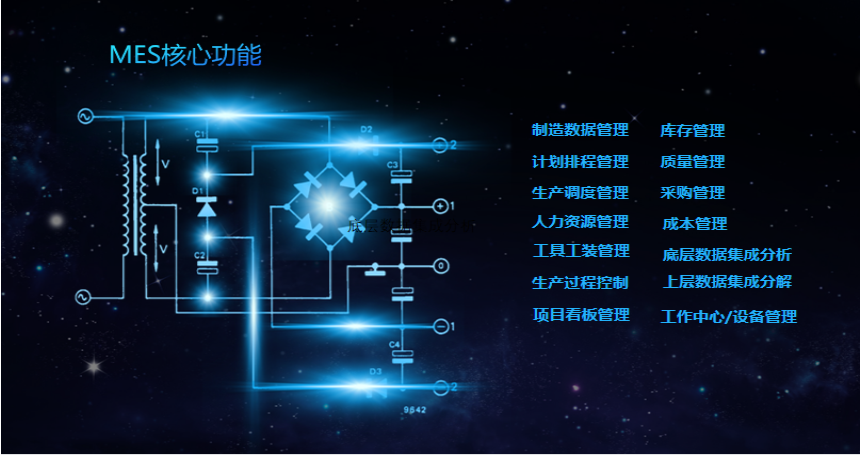

Core functions of the plan

Program Value

It can monitor the entire process from raw materials entering the factory to finished products, record the materials and equipment used in the process, the data and results of product testing, as well as the production time, personnel, and other information of each process. Through MES system analysis, real-time production progress, target achievement status, product quality status, as well as the utilization of personnel, machines, and materials can be presented through system reports, making the production site transparent;

Comprehensive and complete product tracking and traceability function, thereby improving product after-sales service;

Improve the formulation and adjustment of enterprise production plans: Through the production plan management module of MES, improve the efficiency and accuracy of enterprise production plan formulation;

Accelerate the feedback speed of the execution status of enterprise production plans: With process level production plans, the reaction speed of processing information and processing status will be greatly improved during the production and processing of products. After a certain processing process of the product is completed, it will be reflected in the MES system and can be real-time counted, so that the actual production status of the enterprise can be accurately reflected in the first time.

Improving equipment management: Through the MES equipment management module, clear online electronic accounts can be established for all equipment in the enterprise. Record the location of the equipment, its condition, regular inspections, and major repairs.

For further details, please contact us

Consultation hotline:+86-13908307100, 13752990427

Office phone:+86 023 63948774, 63115900, 63115950

Fax:+86-023-67881453

Website: www.jnabs.com

Email: yiekj@yiekj.com

Address: 25th floor, Qibo Building, No. 99 Jinyu Avenue, North New District, Chongqing.